WELCOME TO

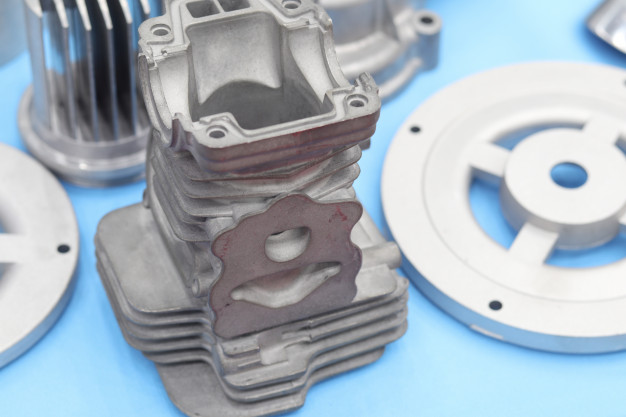

Our company Revolving Techno Cast established together of the leading manufacturers, exporters and suppliers of a huge collection of CI and SGI Castings. New within the business, we proffer a chief range of CI Castings, SGI Castings which are available in several specifications for the entire attainment of clients’ demands.

Dedicated Teams

Our company is well-supported by a team of highly brilliant and competent personnel, which assists us in offering the simplest quality SGI & CI Casting. We believe the right segregation of the whole team.

Best Quality

Raw Material and every one processed material of specified quality utilized in production are analyzed for all incoming materials within the Store dept. 100% inspection of pattern in process in ensured.

HOW IT WORK

Our Work Process

Patternmaking

To create a casting mold, a manufacturer must first design a physical model. the method of fabricating this model is named patternmaking.

Coremaking

Cores are solid materials placed inside the mold cavity to make interior surfaces of a casting. for instance , a metal pipefitting would require a cylindrical core inside the mold cavity to make the hollow construction of the component's interior.

Molding

The manufacturer can create the casting mold. a cloth like sand is employed in expendable mold casting, whereas metal and other durable materials are utilized in non-expendable mold casting techniques.

Melting and pouring

Metal must be properly melted before being placed within the mold. Crucibles are containers made from porcelain or another melt-resistance substance, Then melted metal is poured into the casting mold to chill and harden.

Finishing

Because metal can sometimes fill in cracks during a casting mold or sprues, the pouring channel for the mold. Once proper appearance and surface texture has been achieved, further treatment like painting or electroplating could also be necessary.

Perfect Solutions For Any Industrials